Industry leading high uptime and low maintenance costs Agglomeration Drums

Industry leading high uptime and low maintenance costs. Designed to prepare feeds with high fines content for gold leaching and base metal heap leaching operations.

KEY ADVANTAGES

- Low installation costs with no heavy foundation requirements

- No critical components such as ring gears, chain drive, steel wheels or trunnion bearings

- Standard, off-the-shelf major components to minimize downtime

APPLICATIONS

- Gold Ores – Mixing of lime for pH control

- Copper, Uranium or Nickel Laterite Ores – Organic polymers for binder

Request Information

Contact a Sepro Expert today.

"*" indicates required fields

Product Overview

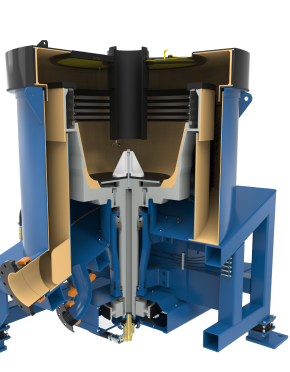

Sepro Tyre Drive Agglomeration Drums are the industry standard for heap leach operations. They are specifically designed to prepare feeds with high fines content for gold and base metal heap leaching operations.

Sepro Tyre Drive Agglomeration Drums are specifically designed to prepare feeds with high fines content for gold and base metal heap leaching operations. The agglomerating action in the agglomeration rotary drum, combined with small additions of cement, lime or organic polymers, binds the fines into an agglomerated pelletized product. This product is then heaped and leached without pooling and channeling caused by loss of heap permeability. Complete with a variable frequency drive (VFD) package, operators are able to fine tune the operation of the Sepro Agglomerator based on the application. No auxiliary drive is required to perform maintenance. Sepro Mineral Systems Agglomerator shells are manufactured in one piece to high quality standards and are thermally stress relieved to eliminate localized high stress areas.

The machine utilizes the Sepro Mineral Systems Pneumatic Tyre Drive System (PTDS) which provides an alternative to standard chain and gear drive systems. This system of rubber tires mounted on independent gearboxes have been proven in numerous difficult applications and have been shown to provide excellent serviceability and reliability. An instrumental feature accompanying Sepro’s tire driven equipment is the Tire Pressure Monitoring System (TPMS), which comes standard with each Sepro rotary control console.

Sepro Tyre Drive Agglomeration Drums are used in a variety of heap leach applications, including:

- Gold Ores

- Mixing of lime for pH control

- Cement for binder

- Cyanide solution

- Copper, Uranium or Nickel Laterite Ores

- Sulfuric acid

- Organic polymers for binder

- Short delivery times

- Low installation costs with no heavy foundation requirements

- No critical components such as ring gears, chain drive, steel wheels or trunnion bearings

- Standard, off-the-shelf major components to minimize downtime

- Commercial heavy truck tyres that can easily be sourced locally

- Units are all pre-assembled and shop tested

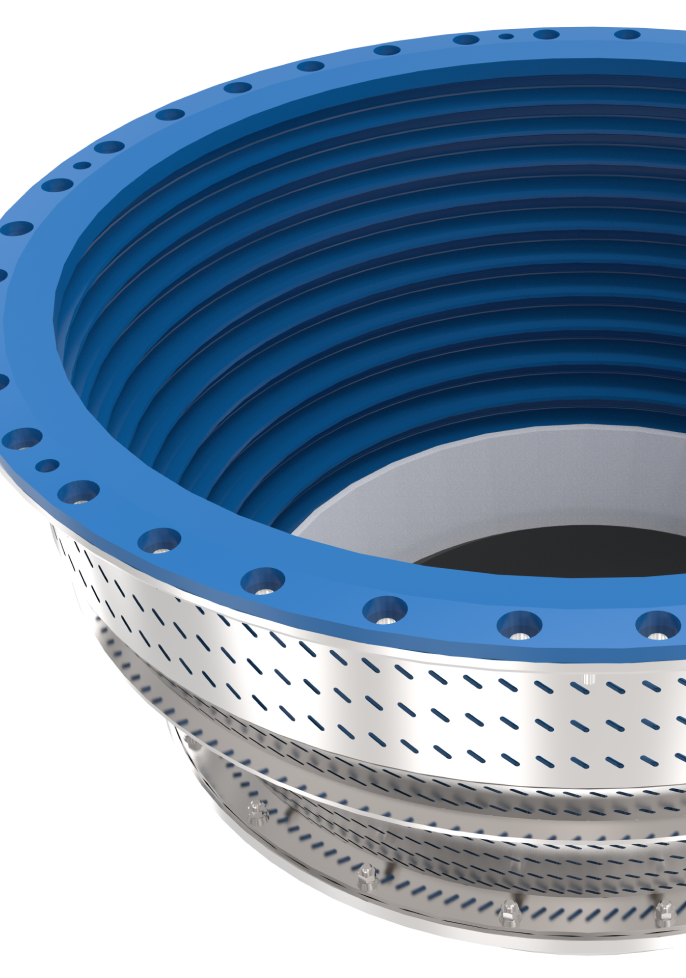

- Flexible rubber drum lining system to prevent buildup

- Shell supported design allows for quick and efficient maintenance

- Drum angle on frame is adjustable to suit application

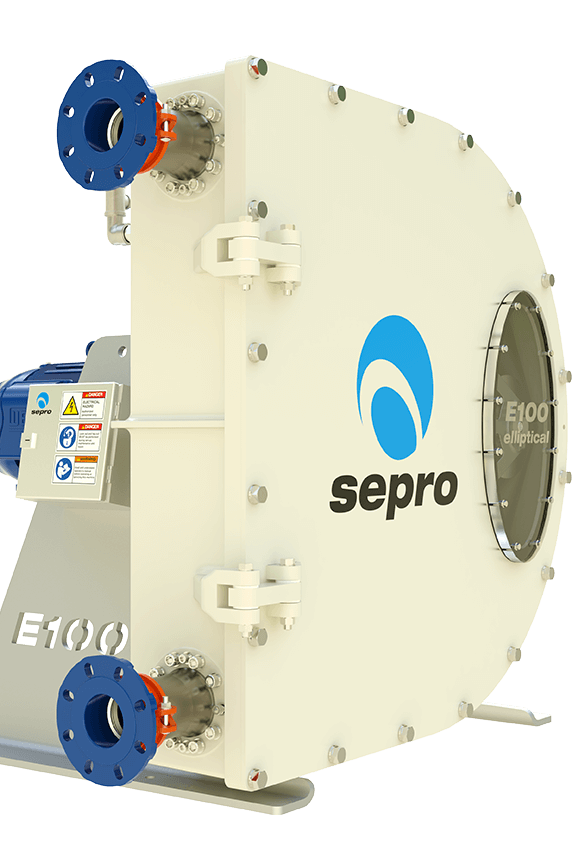

Sepro Mineral System’s line of heavy duty tire driven Agglomeration Drums utilize a powerful and rugged Variable Frequency Drive (VFD) package, allowing operation to be fine-tuned based on the heap leach application. The Rotary Control Console (RCC) component features a touch-screen HMI (Human Machine Interface), which is used to control and monitor the operating parameters. Every Sepro Tire Drive Agglomeration Drum AutoPAC comes complete with a jacking cradle, tire pressure sensors, and hardwired safety limit switches.

Every Agglomeration Drum manufactured by Sepro Mineral Systems comes complete with a Tire Pressure Monitoring System (TPMS). Located within the RCC, the TPMS feature protects the operation from costly downtime due to under-inflated tires. The system works as a closed loop control, allowing the HMI to disable the VFD should the operating conditions of the equipment stray outside of its defined parameters. Monitoring the equipment’s tire pressure greatly improves machine performance and availability over time.

Autopac

Variable Frequency Drive Cabinet (VFDC)

NEMA 12 / IP 51 Enclosure

Vacon NXS VFD w/ Ethernet

Fused Disconnect

Line and Load Reactor

Control Relays

Rotary Control Console (RCC)

NEMA 4 / IP 66 Enclosure, Tire Pressure Monitor System (TPMS)

Red Lion G308 HMI 8.4 Screen w/ Ethernet

Start / Stop / E-Stop Pushbuttons

Control Relays

Five Port Ethernet Switch

Increase your gold recovery today. Speak to an expert

Speak to one of our mineral processing experts today.

Speak to an expert