Higher recoveries and faster cycle times Sepro Leach Reactors

An advanced system for leaching precious metal concentrates generated from gravity concentration circuits. Higher recoveries and faster cycle times than competing leach reactors.

KEY ADVANTAGES

- Streamlined simple intensive leaching design

- Valuable metallurgical benefits

- Completely automated process

APPLICATIONS

- Sepro Leach Reactors are used primarily for gold leaching, the recovery and upgrading of gold from gravity concentrate.

- High concentration cyanide solution is used to dissolve the gold particles into solution. The gold can be recovered from solution by direct electrowinning, carbon adsorption or zinc precipitation as required. This allows high recoveries in a shorter time keeping the footprint small.

Request Information

Contact a Sepro Expert today.

"*" indicates required fields

Product Overview

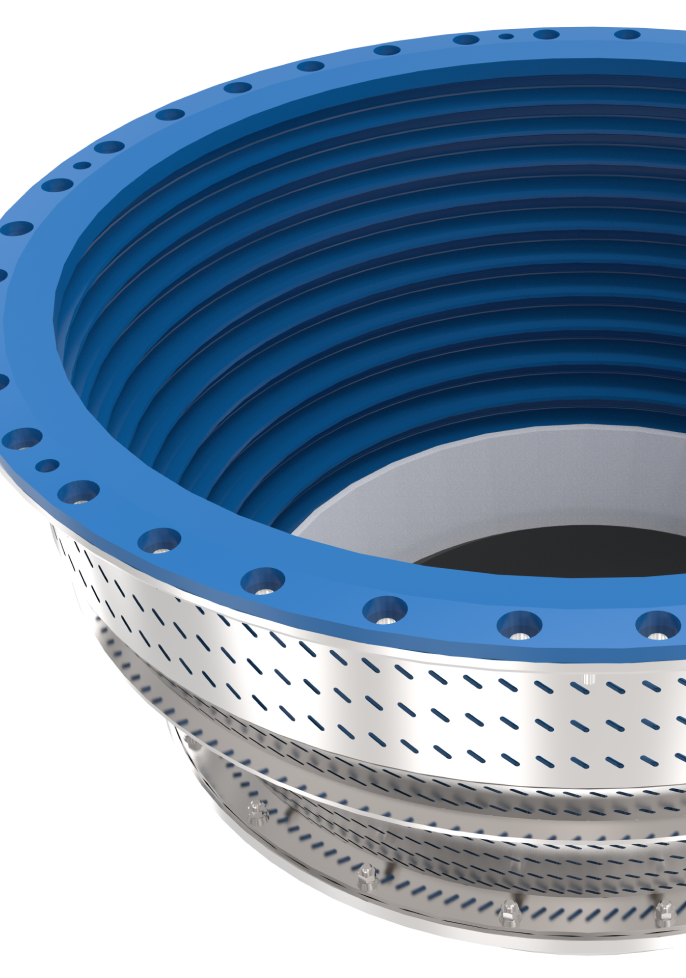

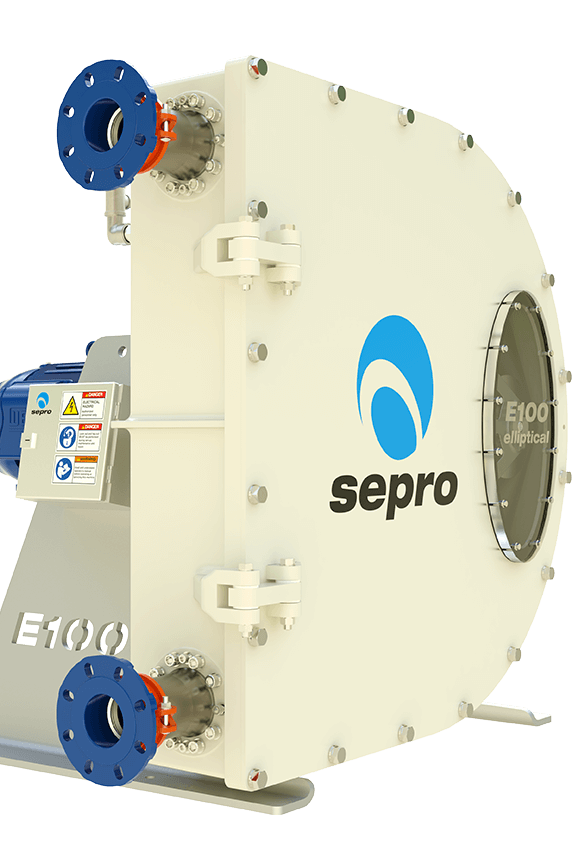

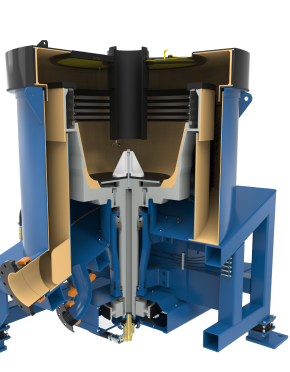

The Sepro Intensive Leach Reactor has several innovative features. It uses a specially designed agitation system to improve leach kinetics while keeping wear rates low. It also has a patented in-tank filtration system to generate a clear pregnant solution without the need for secondary filtration or solution polishing. Taken together, the Sepro Leach Reactor’s quick cycle times and integrated filtration mean more gold production in a smaller footprint.

The Sepro Leach Reactor (SLR) is an advanced leaching system for leaching precious metal concentrates generated from gravity concentration circuits; this includes gold leaching. Extensive test work of the Sepro Leach Reactor on-site has shown over 99% of the target mineral can be recovered through a simple, fully automated process that is easily incorporated into gold and silver recovery operations. Not only does the SLR have low operating costs, it also recovers more gold than conventional physical separation methods.

Laboratory units are also available for agitated leach reactor testing which generate reliable data for scale up to commercial operation. Pilot scale machines are also supplied for field test purposes.

Automation

From concentrate collection to tailings discharge, the Sepro Leach Reactor is a fully automated unit that requires no operator attention. Further, the Sepor Leach Reactor is fully instrumented to control reagent dosages and to monitor for safe operation.

Key Advantages

- Streamlined simple intensive leaching design

- Minimal moving parts

- Agitated tank leach

- Valuable metallurgical benefits

- Clear pregnant solution

- Ideal feed for electrowinning

- No loss of fines

- Leached ore can be returned to circuit

- Barren solution can be reused

- Completely automated process

- Minimal oversight risk

- Continual monitoring for optimal performance

- Hassle free maintenance

- Online instrumentation cleaning and replacement

- Simple pumps used periodically

- Rubber lined mixer and leach tank limits wear

- Optimized safety features

- pH monitor to minimize risk of HCN formation

- HCN monitor for failsafe

Increase your gold recovery today. Speak to an expert

Speak to one of our mineral processing experts today.

Speak to an expert