The optimal choice for high clay mineral ore and stone washing duties Scrubbers

Operating for decades around the world, Sepro Tyre Drive Scrubbers are proven to be the optimum choice for high clay mineral ore and stone washing duties.

KEY ADVANTAGES

- Standard scrubber sizes from 1.2m X 3.0m to 3.6m X 12.0m

- Short delivery times

- No critical components such as ring gears, chain drive, steel wheels or trunnion bearings

- Low installation costs with no heavy foundation requirements

APPLICATIONS

- Processing of wet tropical laterites prior to recovery of nickel and cobalt

- Washing of laterites to liberate fine precious metals for gravity recovery

- Removal of clay from hard rock ores prior to crushing

- Washing of crushed aggregate, gravel and sand to remove clay contamination

- Cleaning of contaminated soil and rubble

Request Information

Contact a Sepro Expert today.

"*" indicates required fields

Product Overview

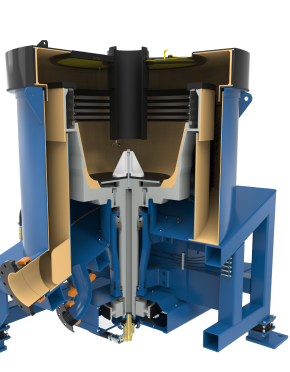

Sepro Tyre Drive Mineral Scrubbers feature a rugged and simple design, incorporating robust components that deliver high availability and low capital and operating costs. Operating in many applications on feeds with high clay contents, Sepro Tyre Drive Mineral Scrubbers are proven to be the optimum choice for difficult mineral ore and stone washing duties. Sepro Tyre Drive Mineral Scrubber shells are manufactured in one piece to high quality standards and are thermally stress relieved to eliminate localized high stress areas.

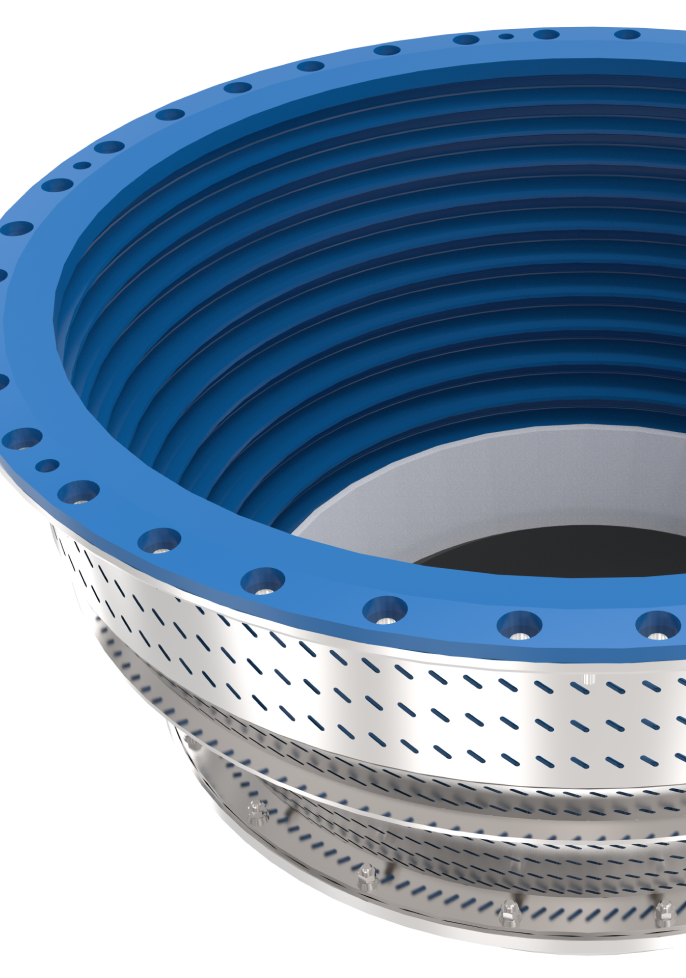

Our scrubbers utilize the Sepro Pneumatic Tyre Drive System (PTD), which provides an alternative to standard chain and gear drive scrubber systems. This system of rubber tires mounted on independent gear boxes provides excellent serviceability and reliability, having been well proven in numerous difficult applications.

Sepro operates pilot scale facilities, which generate reliable data for scale up to commercial operation. Pilot scale machines are also supplied for field test purposes.

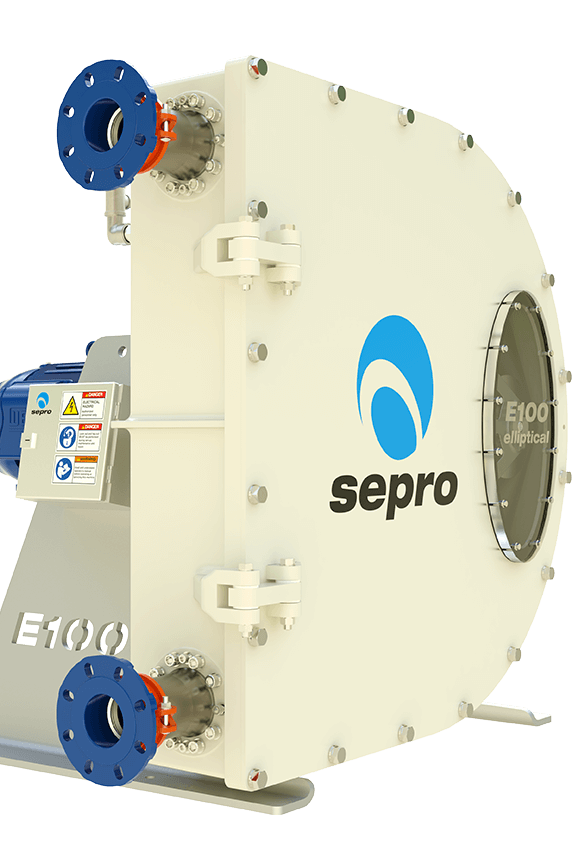

Sepro’s line of heavy duty Tyre Drive Mineral Scrubbers utilizes a powerful and rugged Variable Frequency Drive (VFD) package, allowing operations to be fine-tuned based on the application. The Rotary Control Console (RCC) component features a touch-screen Human Machine Interface (HMI), which is used to control and monitor the operating parameters. Every Sepro Mineral Scrubber AutoPAC comes complete with a jacking cradle, tire pressure sensors and hardwired safety limit switches.

Every Scrubber manufactured by Sepro comes complete with a Tire Pressure Monitoring System (TPMS). Located within theRCC, the TPMS feature protects the operation from costly downtime due to under-inflated tires. The system works as a closed loop control, allowing the HMI to disable the VFD should operating conditions of the equipment stray outside of its defined parameters. Monitoring the equipment’s tire pressure greatly improves machine performance over time.

Increase your gold recovery today. Speak to an expert

Speak to one of our mineral processing experts today.

Speak to an expert