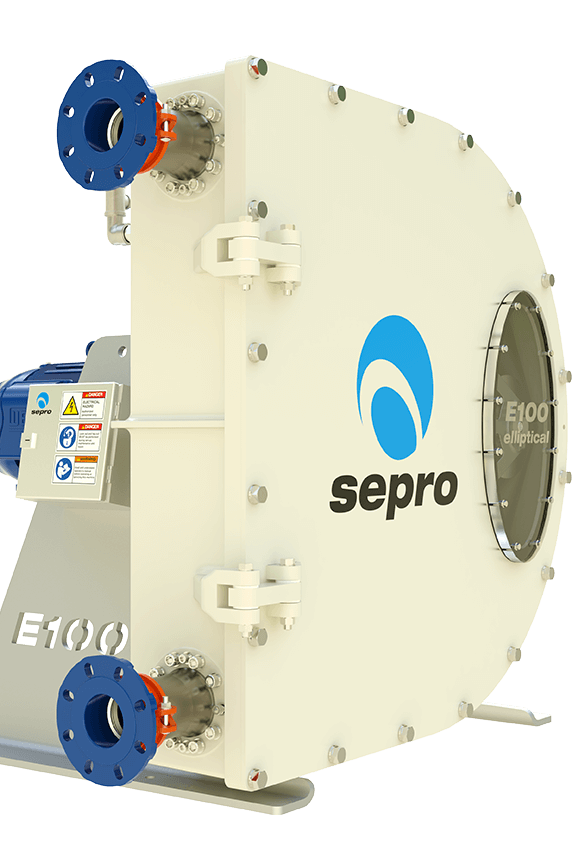

Synonymous with high efficiency, reliable classification and dewatering capabilities. Horizontal Screens

High capacity vibrating screens available in a variety of models and sizes. Our horizontal screens can suit almost any application, whether sizing, scalping or dewatering.

KEY ADVANTAGES

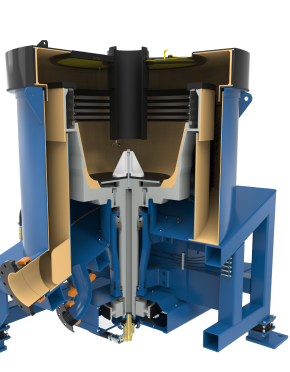

- Low profile screen box design for minimum head room requirements

- Trunnion suspension with heavy duty coil springs

- Directly driven by reliable vibrator motors

APPLICATIONS

- Sepro Horizontal Screens are used for a variety of particle size separation, scalping and dewatering duties.

Request Information

Contact a Sepro Expert today.

"*" indicates required fields

Product Overview

Sepro Horizontal Screens are used for a variety of particle size separation, scalping and dewatering duties. In aggregate applications, proper size separation and dewatering is essential to generate a saleable product. Sepro works closely with clients to determine the correct screen type and size for each application.

Sepro offers high capacity screens available in a variety of models and sizes to suit almost any classifying and dewatering application where specific size and moisture content are paramount.

Sepro Minerals representatives can advise you on the best type of screen media to use depending on your feed product. Options include polyurethane, profile or wedge wire, and pretension framed woven wire panels ? many of which are easily interchangeable and low maintenance.

Automation

Sepro Automation features cutting edge technology and offers superior electrical performance, high availability and durability. Sepro is able to provide all types of controls from small motor starters, up to and including, plant controls and Motor Control Centers (MCC) either supplied loose or installed in containerized e-houses.

Key Advantages

- High capacity

- High frequency linear stroke

- Low profile screen box design for minimum head room requirements

- Trunnion suspension with heavy duty coil springs

- Directly driven by reliable vibrator motors

- Interchangeable screen decks with a variety of screen media options

- Easy deck angle changes

- Possible horizontal or up-hill installation

- Extra rugged screen construction for heavy load operation

- Fabricated from mild steel with huck bolt type fasteners

- Dual and quad vibrating type motors

- Steel vibration isolating springs

- 305 mm x 305 mm standard polyurethane pin and sleeve type screen panels

- Rubber lined discharge lip and cross beams

- Local electrical disconnect

- Spray bar assemblies with polyurethane spray nozzles

- ?Removable end caps and individual shut off valve

Increase your gold recovery today. Speak to an expert

Speak to one of our mineral processing experts today.

Speak to an expert