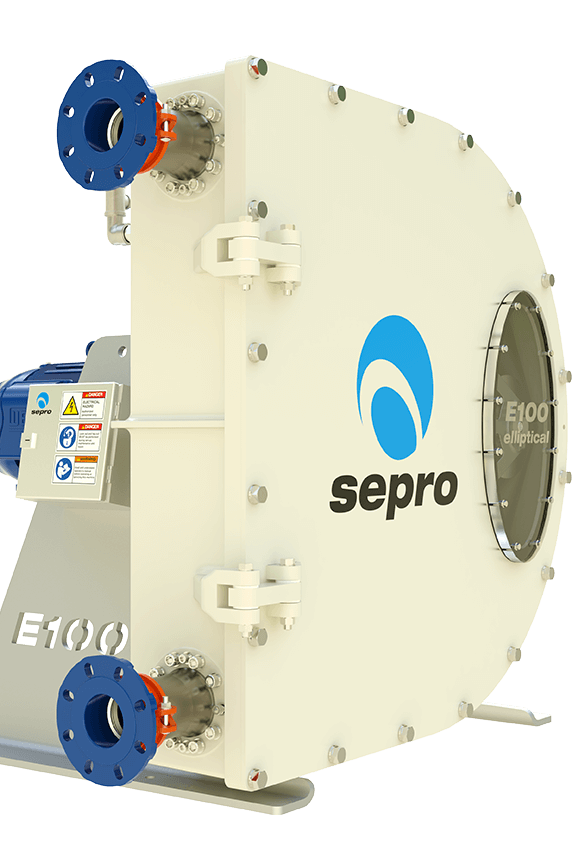

Recover ultra-fine tin, tantalum, tungsten and other challenging minerals Falcon UF Concentrator

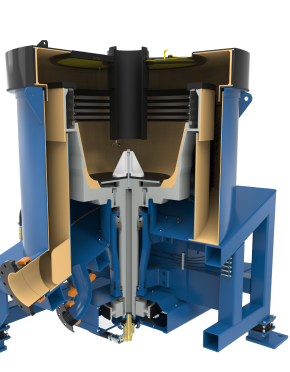

The Falcon UF generates the highest G-force of any gravity concentrator on the market. This exceptionally high force enables selective mineral recovery of particles as fine as three microns. The Falcon UF can recover particles previously thought to be unrecoverable by gravity separation methods.

KEY ADVANTAGES

- The industry’s most enhanced gravity concentration technology for meaningful fine particle recovery

- Can operate anywhere from 50 to 600 Gs

- Greater than 95% mechanical availability

APPLICATIONS

- Recovery of ultra-fine industrial and strategic minerals (tin, tantalum, tungsten, etc.)

- Recovery of ultra-fine gold from carbon flotation concentrate

Request Information

Contact a Sepro Expert today.

"*" indicates required fields

Product Overview

Ultra-fine mineral recovery has been a mining industry goal for many years. Thanks to the Falcon UF Gravity Concentrators, there is now a way to economically recover and upgrade particles as fine as three microns. The primary objective of the Falcon UF Gravity Concentrator is to scavenge ultra-fine mineral particles that are typically rejected from mining plant processes as slimes.

You can expect the following advantages of using the Falcon UF:

Power

- The industry’s most enhanced gravity concentration technology for meaningful fine particle recovery

- Can operate anywhere from 50 to 600 Gs

- Greater than 95% mechanical availability

- Advanced wear materials and a modular design decrease downtime and maintenance costs

Usability

- Recovers particles finer than 10 microns

- Low maintenance costs (even lower than Falcon SB’s)

- Parts costs are expected to be less than $0.01 USD per ton treated

- Concentrate can be cleaned to saleable grades

Efficiency

- No process water required

- Small footprint

- Extremely low operating costs

- Fully automated, one touch operation, minimizes offline time and offers the highest mineral concentrate security

Increase your gold recovery today. Speak to an expert

All Falcon Concentrators are fully automated. Despite having a multi-stage operating sequence, our Concentrators can start and stop with the press of a single button or signal from a plant control centre. In addition, all Falcon Concentrators are fully instrumented to allow for quick process feedback and accurate process control.

A single Falcon UF Concentrator can be (and has been) programmed to act as a rougher, cleaner, scavenger and recleaner when used in conjunction with the appropriate tanks and pumps. Sepro strives to provide exceptional value with all gravity concentrators it sells.

Its groundbreaking technology is very new, what about its mechanical robustness?

Sepro Mineral Systems’ Falcon UF Gravity Concentrator machines run on mechanical platforms that have been proven over almost two decades in plant environments.

What do your model numbers mean?

The model prefix designates the machine type. The suffix is the approximate concentrating surface area of the machine in square inches. A UF1500 Gravity Concentrator is batch unit with approximately 1500 in? of concentrating surface area.

How sharp a separation does the Falcon UF Gravity Concentrator make?

UF Gravity Concentrators are capable of producing extremely high grades of concentrate through multiple concentrating stages. Concentrating ratio at each stage is variable according to mineral, but is usually about 4-10.

What top size should be fed to Falcon UF Gravity Concentrators?

Top size is 38 ?m. Falcon UF’s are specifically designed for recovery of extremely fine minerals, down to 5 microns and less. If your separation involves target minerals coarser than 1 mm, it would be best to look at other technologies for the coarse fraction.

Are there ‘gravity-only’ flowsheets available?

Yes, Sepro Mineral Systems has developed unique flowsheets to help clients achieve previously unobtainable recoveries without using any reagents such as cyanide.

Speak to one of our mineral processing experts today.

Speak to an expert