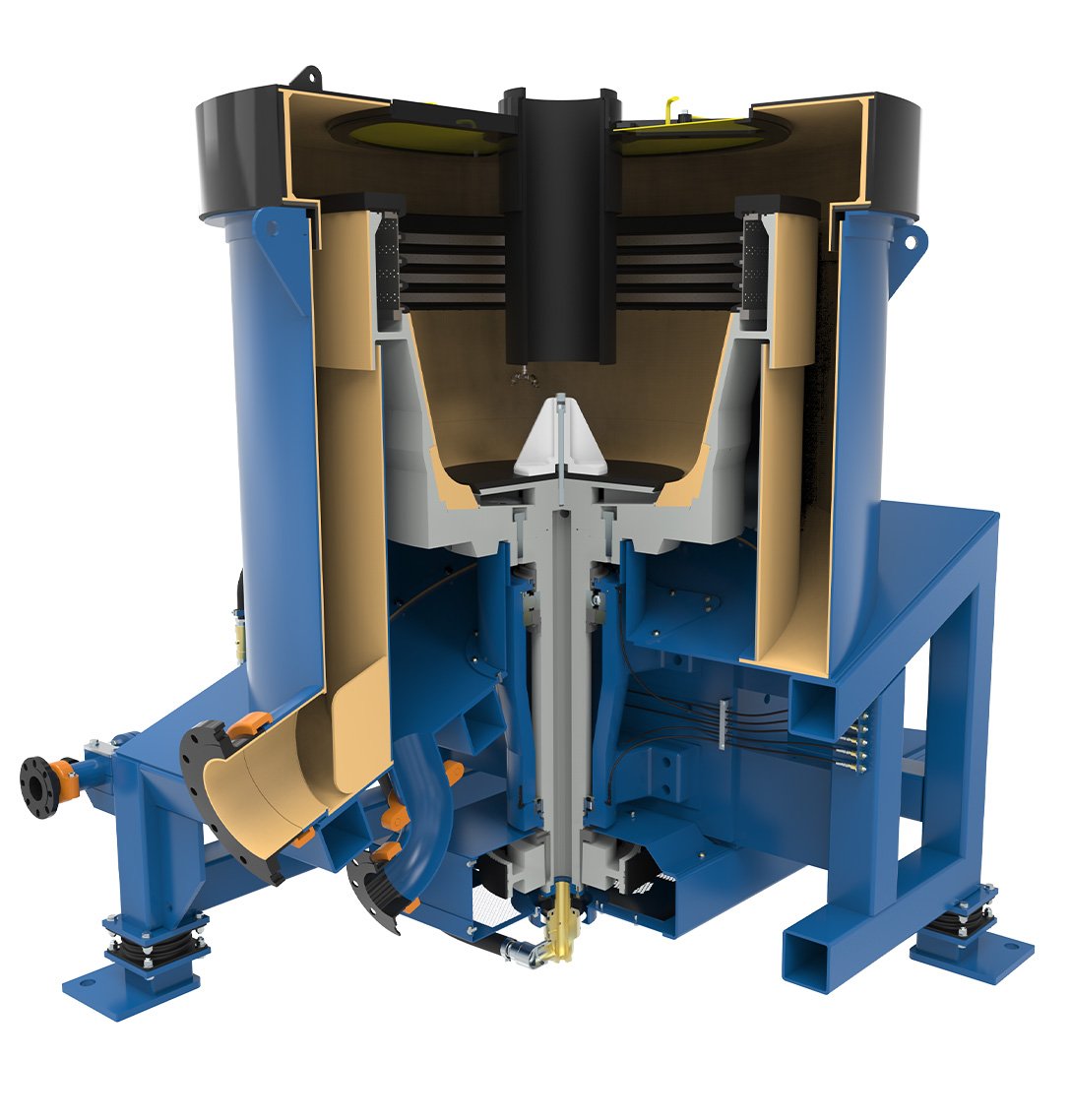

Recover coarse and fine gold, silver and platinum groups metals Falcon SB Concentrator

Falcon SB Gravity Concentrators are known as Semi-Batch Gravity Concentrators because they continually accept feed during the run cycle, but only produce mineral concentrate during periodic rinse cycles.

KEY ADVANTAGES

- Highest G forces available in the mineral processing industry

- Upgraded standard fluidization control results in a higher degree of machine management

- Fully automated, one touch operation, minimizes offline time and offers the highest mineral concentrate security

APPLICATIONS

- Recovery of gold, silver and platinum group metals

- Recovery of gold from cyclone feed, underflow or overflow within the grinding circuit

- Recovery of gold in alluvial gold operations

- Recovery of gold from aggregate plants

Request Information

Contact a Sepro Expert today.

"*" indicates required fields

Product Overview

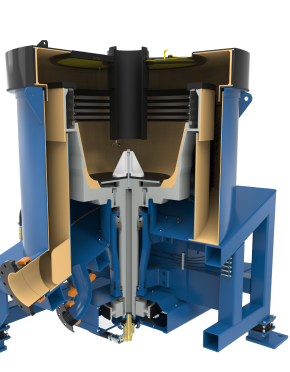

A typical application for a Falcon SB Gravity Concentrator is recovering liberated precious metals (Au, Ag, Pt, etc.) within a grinding circuit. Outside grinding circuits, Falcon SB Gravity Concentrators are also used for precious metal separation from aggregate or placer deposits.

Falcon SB Gravity Concentrators are known as Semi-Batch Gravity Concentrators because they continually accept feed during the run cycle, but only produce mineral concentrate during periodic rinse cycles.

Expect the following with your Falcon SB Gravity Concentrator:

Power

- Highest G forces available in the mineral processing industry

- Can operate between 50 and 200Gs

- Unit capacities up to 400 t/h

Usability

- Upgraded standard fluidization control results in a higher degree of machine management

- Great for when the target mineral is in extremely low concentration

- Built to handle overloading

Efficiency

- Flat lid modular design increases wear life and maintenance costs

- Low water consumption

- Fully automated, one touch operation, minimizes offline time and offers the highest mineral concentrate security

Increase your gold recovery today. Speak to an expert

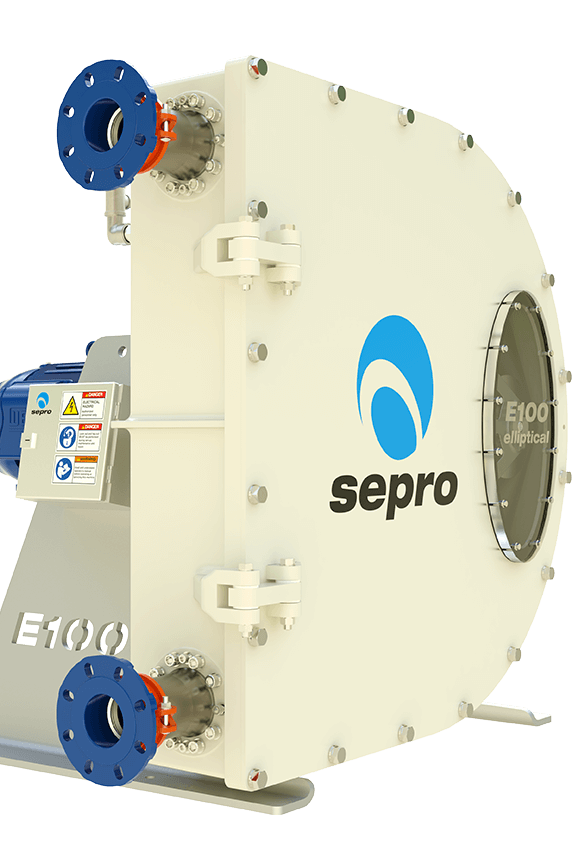

All Falcon Concentrators are fully automated. Despite having a multi-stage operating sequence, the Falcon Concentrators can be started and stopped with the press of a single button or signal from a plant control centre. Further, all Falcon Concentrators are fully instrumented to allow for quick process feedback and accurate process control.

All Falcon SB concentrators are equipped with a dynamic brake which provides quick deceleration and acceleration during the rinse cycle and results in the highest uptime and utilization of any gravity concentrator in the industry.

What operating costs can be expected?

The simple and robust design of the Falcon SB Gravity Concentrator means that unit operating costs are the lowest in the industry, normally a few cents per tonne treated.

What operating availabilities does Sepro Mineral Systems equipment attain?

Sepro Mineral Systems maintains mechanical availability >95% if equipment is installed and maintained according to our recommendations.

What do your model numbers mean?

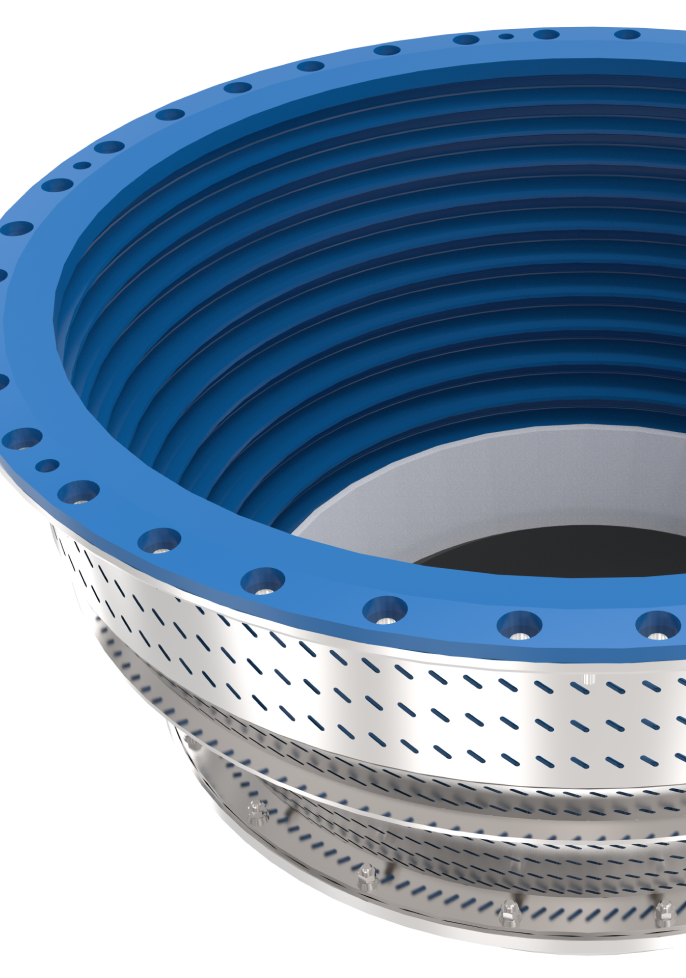

The model prefix designates the machine type. The suffix is the approximate concentrating surface area of the machine in square inches. A SB5200 Gravity Concentrator is batch unit with approximately 5200 in? of concentrating surface area.

What top size should be fed to Falcon SB Gravity Concentrator machines?

Maximum tolerable size for Falcon SB Gravity Concentrators is 6 mm but Sepro strongly recommends reducing the top size to 2 mm or less in most situations.

Are there ‘gravity-only’ flowsheets available?

Yes, Sepro Mineral Systems has developed unique flowsheets to help clients achieve previously unobtainable recoveries without using any reagents such as cyanide.

See the Falcon SB350 in action,

Speak to one of our mineral processing experts today.

Speak to an expert