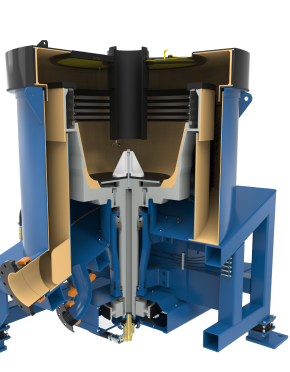

Recover tin, tantalum, tungsten, chrome, cobalt, iron, fine oxidized coal and uranium Falcon C Concentrator

For mineral recovery applications that require a high mass yield to mineral concentrate ratio.

KEY ADVANTAGES

- Unit capacities up to 60 t/h

- Advanced wear materials and a modular design decrease downtime and maintenance costs

- High gravitational field (up to 300 G) allows recovery of very fine particles

APPLICATIONS

- Primary concentration of tin, tantalum, tungsten, chrome, cobalt, iron, fine oxidized coal and uranium

- Scavenging of fine particles lost by low G force processes and flotation

- Pre-concentration of heavy minerals

Request Information

Contact a Sepro Expert today.

"*" indicates required fields

Product Overview

Falcon C Gravity Concentrators are primarily used to maximize mineral recovery and reduce tonnage to downstream processes. The Falcon C is capable of collecting fine minerals that would be missed by dense medium separators, spirals and other low G processes.

The Falcon C provides you with:

Power

- Unit capacities up to 60 t/h

- Advanced wear materials and a modular design decrease downtime and maintenance costs

- High gravitational field (up to 300 G) allows recovery of very fine particles

- Able to produce concentrate mass yields as high as 40%

Usability

- Fine mineral recovery down to 10 microns

- Fully automated, one touch operation, minimizes offline time and offers the highest mineral concentrate security

- Continuous production of concentrate at >70% solids

- Ideal for scavenging and pre-concentrating mining applications

Efficiency

- No fluidizing water consumption or offline time for concentrate flushing

- Produces high density concentrate (60-70% solids) therefore no thickeners are required

- Greater than 95% mechanical availability and extremely low operating costs

- Small footprint

All Falcon Concentrators are fully automated. Despite having a multi-stage operating sequence, our Concentrators can start and stop with the press of a single button or signal from a plant control centre. In addition, all Falcon Concentrators are fully instrumented to allow for quick process feedback and accurate process control.

What is Falcon C Gravity Concentrator technology?

Falcon C (Continuous) Gravity Concentrator technology is a family of truly continuous enhanced gravity concentrating machines that has been proven in commercial applications to be able to withstand 300G concentrating fields while delivering superior metallurgical and mechanical performance at throughputs in excess of 100 t/h. Each machine consists of a single moving part. A feed stream enters the machine and is divided into high and low density fractions. Proportioning of exit streams is continuously variable by the operator.

Does this gravity concentrator consume process water?

No. Model C Falcon Gravity Concentrators require no fluidization water. The dense fraction is produced at pulp densities usually in excess of 70% solids and is well deslimed.

What operating costs can be expected?

The simple and robust design of the Falcon C Gravity Concentrator means that unit operating costs are the lowest in the industry, normally a few cents per tonne treated.

What do your model numbers mean?

The model prefix designates the machine type. The suffix is the approximate concentrating surface area of the machine in square inches. A C2000 is a continuous unit with approximately 2000 in? of concentrating surface area.

What top size should be fed to Falcon C Gravity Concentrator machines?

Top size is 1 mm. Falcon C Gravity Concentrators are specifically designed for recovery of very fine minerals, down to 20 microns and less. If your separation involves target minerals coarser than 1 mm, it would be best to look at other technologies for the coarse fraction.

Are there ‘gravity-only’ flowsheets available?

Yes, Sepro Mineral Systems has developed unique flowsheets to help clients achieve previously unobtainable recoveries without using any reagents such as cyanide.

Increase your gold recovery today. Speak to an expert

Speak to one of our mineral processing experts today.

Speak to an expert