Sepro Mineral Systems Corp. is pleased to announce the build and delivery of 3 separate 3.6m x 10m Tyre Drive Agglomeration Drums has been completed. Sepro technical service representatives are currently overseeing the installation and commissioning phases of the 3 machines in their respective locations of Indonesia, Mexico and Peru. The 3.6 x 10 Agglomeration Drum is currently the largest size mineral processing offering manufactured by Sepro Mineral Systems. Delivering and installing large mineral processing equipment is often challenging. However, our logistics team is knowledgeable of international trade and shipping laws for quick and convenient delivery and installation of even the largest mineral processing equipment.

Sepro Tyre Drive Agglomeration Drum Specs

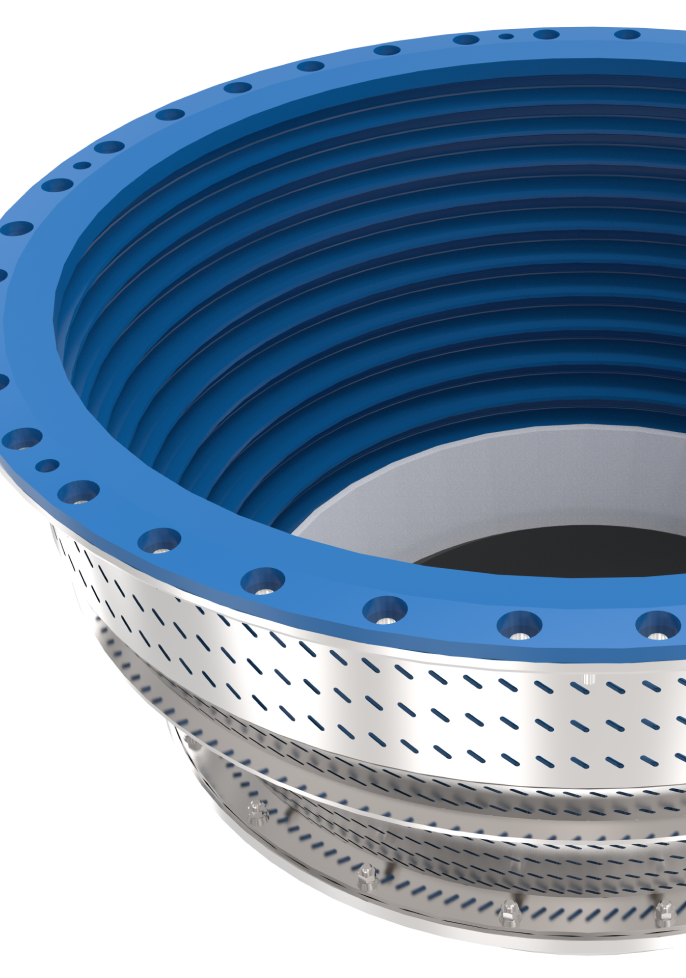

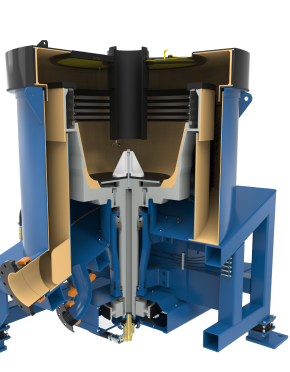

The new Sepro Tyre Drive Agglomeration Drums incorporate standard off the shelf major components, however where requested, customized features were added to support client specific requirements. 2 of the 3 Agglomeration units feature a newly developed Sepro manufactured liner that is offered as a more affordable option to traditional alternatives. Previously used in Sepro supplied Falcon Gravity Concentrators, the liner material has demonstrated longer lasting wear resistance, reduced downtime and opportunities for all around cost savings.

In addition, the Agglomeration Drums incorporate multiple angle settings to adjust the slope of the drum. This feature allows the end user to have flexibility when monitoring the required speed and tonnage by adjusting the drum to a shallower or steeper slope as needed. Finally, in one particular case, a client had requested a redesigned discharge chute to work with their conveyor system. The Sepro team was able to identify a unique solution that met the client’s requirements without compromising the performance of the machine which will work with their existing conveyor system.

Installing Heavy-Duty Mineral Processing Equipment

Installation and commissioning of all 3 Sepro Tyre Drive Agglomeration Drums is expected to be completed with support from the Sepro Technical Service and Automation teams by mid-2017. Sepro Mineral Systems Corp. proudly manufactures Tyre Drive Agglomeration Drums in multiple sizes offered at low capital costs and short delivery times.

Sepro Tyre Drive Agglomeration Drums are specifically designed to prepare feeds with high fines content on Gold and base Metal heap leaching operations. The Action in the Agglomeration Drum, combined with small additions of cement and lime, binds the fines into an agglomerated product. To learn more contact a mineral processing expert today or visit the official mineral processing equipment page.

Contact Sepro Mineral Systems Corp.

Office: +(1) 604.888.5568

Facebook????LinkedIn????YouTube