A combination of Falcon Continuous and Ultra-Fine Concentrators were able to increase overall plant recovery by more than 4% by increasing fine (-300 micron) and ultra-fine (-20 micron) particle recovery.

Featured Equipment

- 1 x Falcon C1000

- 1 x Falcon C400

- 1 x Falcon UF600

Background

The area in and around the historic Tanco mine in Canada’s central province of Manitoba is currently a hotbed of lithium exploration. However, the mine has a long history of caesium and tantalum production dating back to the 1920s. While commercial tantalum production ceased in the early 2010s Tanco served as an excellent example of fine mineral recovery for over a decade.

Challenges

Tantalum breaks down into extremely fine particles after grinding

Substantial losses were observed in the -300 + 20 micron size fraction that was being treated with shaking tables and spirals.

Shaking tables have low unit capacity and take up a lot of floor space

The ultra-fine -20 micron size fraction had high flotation recovery, but could not reach saleable grade.

Flotation concentrate cleaning with a Mozley MGS and crossbelt concentrator could only achieve 50% recovery with an upgrade ratio of 5.

Solutions

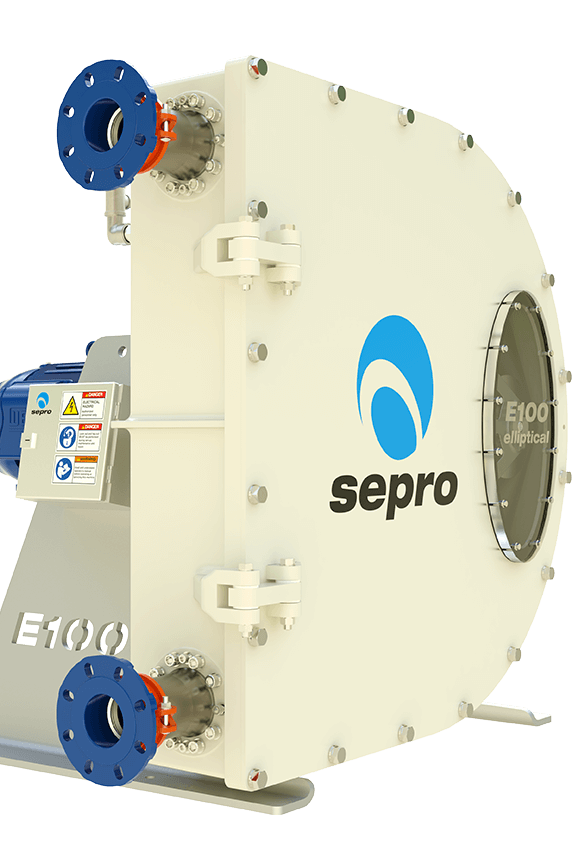

The Falcon Continuous Concentrator, Kelsey Jig and Knelson Concentrator were tested on the -300 + 20 micron size fraction

The Falcon Continuous Concentrator was selected due to the metallurgical performance and low maintenance cost

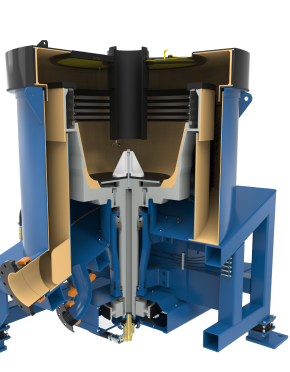

A Falcon C1000 rougher, C400 cleaner and shaking table re-cleaner circuit was commissioned on the -300 +20 micron tailings stream

And additional Falcon C1000 and C400 circuit was commissioned in the spodumene circuit for tantalum recovery

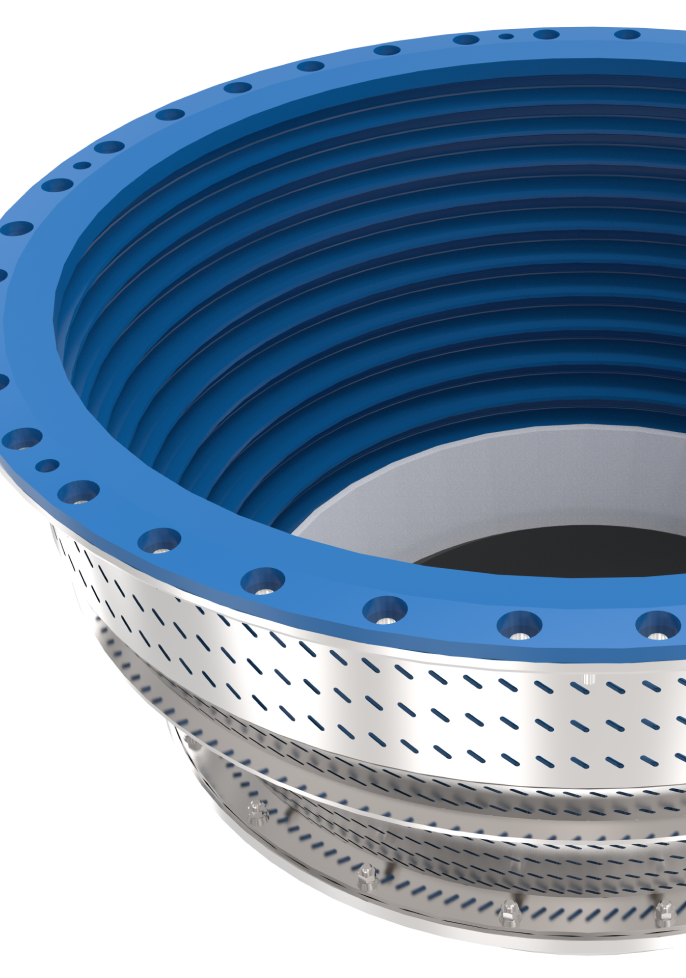

A Falcon UF gravity concentrator was installed to clean the ultra-fine flotation concentrate.

A single unit was automated in conjunction with tanks and pumps for multi-stage operation (roughing, cleaning and scavenging)

Results

Achieved an additional 4% in overall plant recovery with the addition of the Falcon Continuous gravity concentrators

QEM scan revealed no liberated tantalum in the Falcon tailings stream

100% availability since maintenance could be performed within existing preventative maintenance schedule.

Recoveries of up to 80% were achieved with upgrade ratios over 16 in the ultra-fine flotation concentrate